Checklist method

Application of the checklists method allows the verification of compliancy with basic safety precautions by small plants as well as the verification of compliancy of complex industrial plants with additional plant safety precautions because of the modular structure of the checklists.

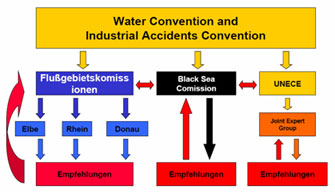

Suitable checklists were formulated based on the recommendations of the river basin committees (UNECE, see above).

- Recommendations for Functional units (e. g. storage, sealing systems, fire prevention etc.)

- Recommendations for Branches (e. g. cellulose industry)

- Recommendations for Risk areas (e. g. contaminated surfaces)

The checklists are divided into three major parts.

- The first part is the organizational and technical recommendations. These will be quoted from the original text.

- The second part is the method of querying to ascertain if the recommendations are complied with.

- The measures to be taken are recommended according to the problem. These are organizational and technical measures which are graded in short-, medium- and long-term measures. They can be used by plant operators as investment plan and by the authority as catalogues of demand.

The checklists should be seen as "living documents". The checklists can and should be revised and improved upon by applying them in the daily practice.

The application of the checklists can also help in detecting those problems that have not been considered during the plant checks and this can lead to the formulation of new recommendations. Also new information and findings of the river basin committees and other international committees which are to be published as recommendations can be considered when revising the checklists.

The constant actualization and improvement of the checklists method is thereby guaranteed.

» Projekt

» Recommendations

» Functional units

» Risk areas

» Branches

» Checklists

» Functional units

» Risk areas

» Explanations

» Trainings

» Refineries

» Real Risk